|

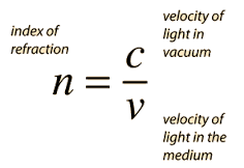

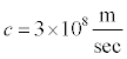

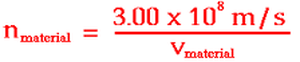

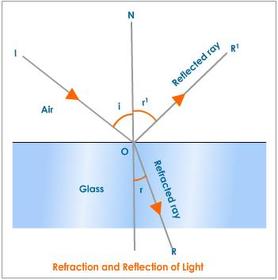

The basic optical property of a material is the index of refraction. It is also one of the key parameter that needs to be key-in into OTDR as to get accurate result on actual fiber optics distance measurement. The index of refraction (n) measures the speed of light in an optical medium. The speed of light (c) in free space or vacumm is Therefore index of refraction of a material is equivalent to :- When light enters a different material ( from glass into air or from air into glass)is the speed changes. This causes the light to bend or refract. Light will always travel slower in the fiber material than in air. The index of refraction for glass is approximately 1.50 or lower.

The index of refraction for air is exactly 1.00. In order to get the actual fiber optics length measurement using OTDR, one is required to enter fiber optics index of refraction into one of OTDR key parameters. The fiber optics index of refraction could be obtained from the fiber optics cable manufacturer.

0 Comments

|

AuthorI have been in the field of fiber optics since early 1990s. I gained fiber optics skills and knowledge via my working experience as end-user, main contractor and sub-contractor and finally as an optical fiber enterpreneur. Archives

January 2017

Categories

All

|

RSS Feed

RSS Feed