|

Conventional rail tracks are laid by fixing rails to sleepers laid on a ballast trackbed. Now, a team of researchers at the UK’s University of Huddersfield are developing modular, all-steel track sections that can be laid quickly and embedded with fiber optic technology, to provide instant safety alerts. They say the approach could lead to “massive cost savings and advantages in safety and efficiency”.

The Institute of Railway Research(IRR), headed by Professor Simon Iwnicki, is based at the University and is one of the partners in a €15 million, four-year project funded by the EU under its Seventh Framework Programme. Capacity4Rail aims to ensure that railways will continue to meet Europe’s transport needs, with development aims including reducing maintenance, more resilient and easily repairable points (switches), and higher-speed freight wagons. There are 47 partners, including major technology companies and European universities, and the University of Huddersfield’s IRR is working on a project entitled “modular integrated design of new concepts for infrastructure”. One of the IRR’s tasks will be to help in the development and design requirements of new track systems. Smart approach The Institute’s Head of Research, Dr Yann Bezin, commented, “We are looking at more efficient designs and methods of building a track, in a modular way rather than by laying down ballast layers and then individual sleepers and putting the rails on top. That takes a long time and requires very expensive and heavy machinery. Modular concepts allow track to be brought pre-assembled in sections for a quick installation. “A big problem is vertical support of the track,” explained Bezin. “Currently you get deterioration from one sleeper to the other or the ballast degrades and some sleepers become unsupported. A concrete sleeper is the norm, but we have studied a steel track system that uses steel beams. This gives consistency of support and better control of dynamic forces.” Bezin added that the construction of modular track sections in the factory would mean that they could be pre-equipped with smart technology. “We could make the track system intelligent. Fiber optics running along the rail would enable a network operator to know from the signal whether or not there is an unusual deformation, an indication of fatigue cracking or some other problem”. Such a condition monitoring system would simplify maintenance, adding to the efficiency gains from modular track construction. Capacity4Rail The IRR will receive more than €470,000 for its contribution to Capacity4Rail. In addition to work on modular track sections, the Institute’s researchers, who are based in specially equipped labs at the University of Huddersfield, will study new designs for the construction of switches and crossings. The IRR will be investigating resilient new materials for crossings and switches, working with the metallurgist Jay Jaiswal, formerly of Tata Steel, who has been appointed a visiting professor at the University of Huddersfield. The Institute will also be working with major companies such as Systra, which has constructed all of France’s and half of the world’s high-speed lines. The Capacity4Rail research will build on the findings of previous projects that the IRR has been closely involved with, such as the EU-backed Innotrack, which has investigated many of the technical challenges posed by the EC’s goal of doubling rail passenger traffic and tripling freight traffic by 2020. About the Author Matthew Peach is a contributing editor to optics.org.

1 Comment

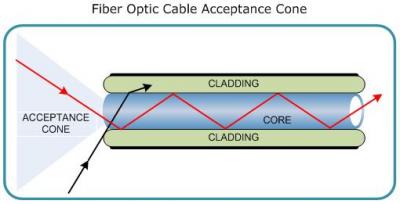

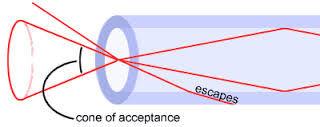

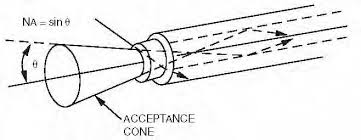

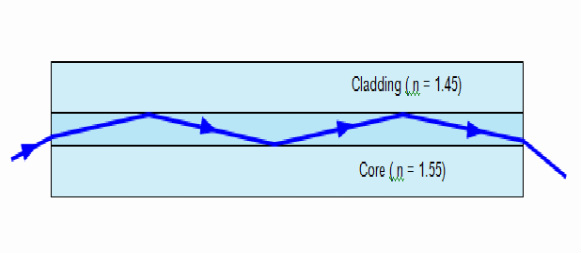

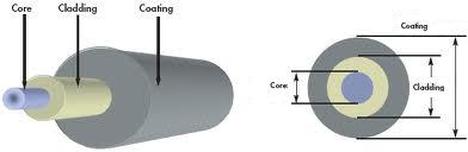

Only light that enters the fiber core within a certain range of angles or other known as critical angle or acceptance cone, can be successfully travelling through the length of the fiber. The light that does enter the fiber core but not within the acceptance cone will normally escape or lost into fiber optics cladding. The size of acceptance cone is a function of the refractive index difference between the fiber optics core and cladding. where n(core) is core refractive index and n(cladding) is cladding refractive index.

However, all these factors are being taken care with due diligence during the designing and manufacturing process of fiber optics preform. The core transmit the light. In order to contain the light within the core, both cladding and the core are both manufactured with two difference refractive index values as shown in the above diagram. Generally the core refractive index is higher than the cladding refractive index.

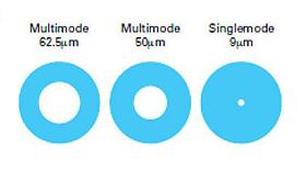

How big is a MICRON ? Basically human hair size is approximately 100 micron but the size of both multimode and singlemode core size is 50 micron or 62.5 micron and 9 micron respectively.

One can conclude that human hair size is thicker than the size of fiber optics core !!! Fiber Optics is made of 2 main components or structures.

They are :- a. Core b. Cladding Both structures are made of glass. Another layer of coating is applied over fiber optic cladding to protect against abrasion and damage. Normally coating is made of plastic or other compound. Disadvantages of Fiber Optics Training Technicians working with fiber optics require special tools and thus require constant training on skills and knowledge. Extra Care Fiber Optics require extra precaution during handling. Mishandling cause fiber optics to increase its loss unnecessary and thus degrade the performance of fiber optics communication system. Cost Cost of fiber optics cables on per km basis is definitely going down due to high demand plus the abundant availability of silica but the cost of transmitter and receiver devices still on higher side. Special Tools & Test Gears

Fiber Optics require special tools for jointing and termination purpose plus special test gears for testing, troubleshooting and maintenance. The total cost of these tools and test gears could easily amounting to thousands of dollars. Benefits Of Fiber Optics Long Distance Signals in fiber optics can be transmitted over a distance up to 100 km without any needs to install repeaters or amplifiers. Weight and Size The outer diameter of fiber optics cable can be up to 1 mm or more depending on the number of fiber optics count. Basically 36 pairs or 72 fiber optics strands can be bundled into 1 mm cable diameter. For one pair of fiber optics, million of phone calls can be transmitted globally. Ground Isolation There is no need for ground isolation as eletrical currents do not flow into fiber optics cable. Lightning Protection Fiber optics signals do not conduct electricity as such lightning has no effect on its signals. Cost Benefits Cost of installing on long-distance fiber optics cable is far cheaper as fiber optics can be installed up to 100 km without any repeaters or amplifiers in between. Security Fiber Optics signals do not radiate electromagnetic signals. As such eavesdropping or tapping is virtually impossible. Safety Fiber Optics signals are intrinsically safe as the signals do not cause spark or emit electromagnetic signals. Cable Routing Fiber Optics cables do not conduct electricity thus they can be installed on the same cable tray as power cables. Noise Immunity Fiber optics are immune to electromagnetic noise coming from welding discharges, electrostatic dischargers and other radio frequency interference. Fiber Optics is a dielectric material and not susceptible to electrical interference. Bandwidth

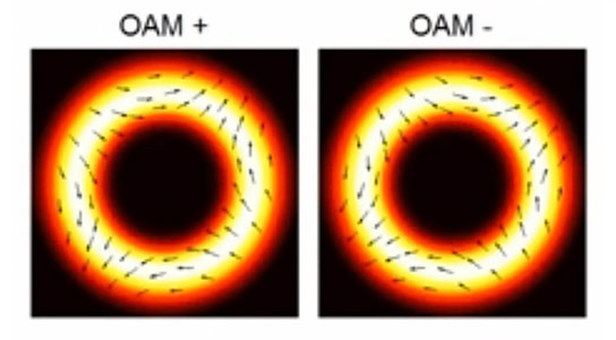

Fiber Optics are able to carry high data rate up to 1 Tb/s in which no other medium can match fiber optics capability.  Researchers were able increase data flow through fiber optic cables by moving light through them in a spiral motion, rather than a straight line. Credit: P. Gregg New fiber optic technology from researchers at Boston University and the University of Southern California could ease Internet congestion and boost Internet bandwidth. As rapidly increasing demand for bandwidth strains the Internet’s capacity, a team of engineers has devised a new fiber optic technology that promises to increase bandwidth dramatically. The new technology could enable Internet providers to offer much greater connectivity – from decreased network congestion to on-demand video streaming. Adapted from Scitechdaily.com

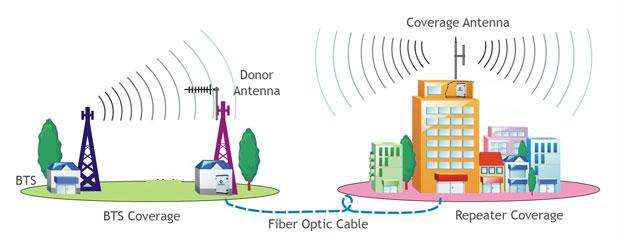

Be it wireless or satellite network, fiber optics communication is hardly not being noticed by any telecommunication system installers. It is now being apart of any telecommunication networks to smoothly transfer large amount of data , video and voice from one end to the other end.

|

AuthorI have been in the field of fiber optics since early 1990s. I gained fiber optics skills and knowledge via my working experience as end-user, main contractor and sub-contractor and finally as an optical fiber enterpreneur. Archives

January 2017

Categories

All

|

RSS Feed

RSS Feed