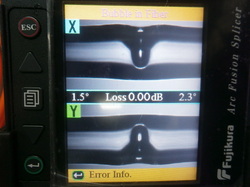

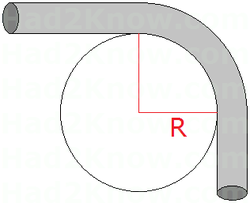

Here are top 5 most common fiber optics failures 1. Dirty Fiber Optics Connectors Always clean your fiber optics connector end ferrule surface with appropriate cleaning device such isoprophyl alcohol or other recommended tools.  2. Poor Polishing Always check and observe your fiber optics connector end ferrule surface with fiber optics microscope.  3. Mislabelling Always check your fiber optics continuity end-to-end or connector-to-connector by using either VFL or power meter & Light source  4. Bad Splicing Always double check your fusion splicing loss with an OTDR to get accurate readings. Readings appeared on splicing machine are only indication or estimation.  5. Excessive fiber bendings Always double check your fiber otpics management either in fiber optics termination box or fiber cable route. Try to minimise the bending as much as possible as too small bending will result in higher fiber otpics dB loss.

0 Comments

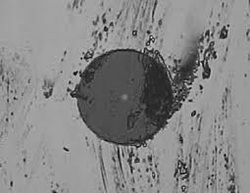

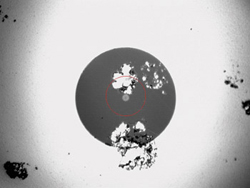

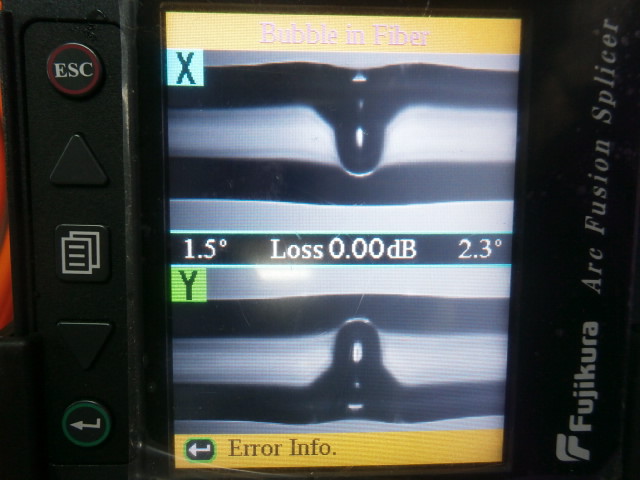

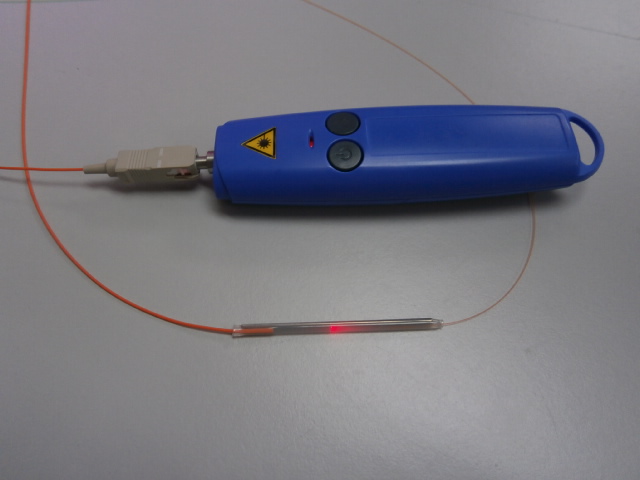

Image of a bubble at the fusion splice between two ordinary multimode fiber optics. This bubble causes extreme fiber optics splicing high loss as shown visually via Visual Fault Locator (VFL) on the right hand side image.

This bubble resulted from dirt on the fiber end surface. Proper care should be taken care of during cleaning process of fiber optics by using appropriate cleaning device such as isoprophyl alcohol. It is better to redo the splicing immediately so as to obtain minimum splicing loss possible. |

AuthorI have been in the field of fiber optics since early 1990s. I gained fiber optics skills and knowledge via my working experience as end-user, main contractor and sub-contractor and finally as an optical fiber enterpreneur. Archives

January 2017

Categories

All

|

RSS Feed

RSS Feed