|

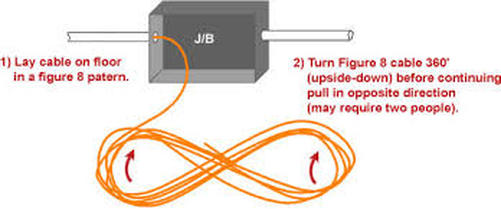

It is has become a norm in telecommunication industry whereby we will see groups of electrical engineers, copper & wireless installers are closely becoming involved with fiber optic installation, termination and testing & commissionning. Once we fully understand the simple fiber optics guidelines then the process of installation, termination & testing would be easier to handle. Please use following guideliines in order to secure maximum fiber optics cable performance, a. Never kink the cable. b. Never exceed recommended bend radius during or after installation. If during cable pulling the minimum radius is 20 x than the cable outer diameter and 10 x when cable at rest. c. Do not exceed recommended tensile loads. Use external pulling grips so as the load is applied to the cable strength member and not unto the fiber itself. e. Monitor tensile loading or pulling force. f Avoid pulling long lengths in one direction. f. Do not crush put pressure on the cable. g. Plan to install extra cable protection in high-risk areas such as HDPE conduit. h. Always secure cables in all installations over ceilings or under floors. i. Survey and plan all cable routes in order to protect cable against rodents or external stress or pressure. j. Comply with all regulatory requirements and fire codes.

1 Comment

Mark Banner

8/2/2019 04:26:54 pm

Thanks for sharing with us this informative post on <a target=”_new” href=”https://yamasakiot.com”>fiber optic</a>. From your blog, we get much valuable information on this topic.

Reply

Leave a Reply. |

AuthorI have been in the field of fiber optics since early 1990s. I gained fiber optics skills and knowledge via my working experience as end-user, main contractor and sub-contractor and finally as an optical fiber enterpreneur. Archives

January 2017

Categories

All

|

RSS Feed

RSS Feed